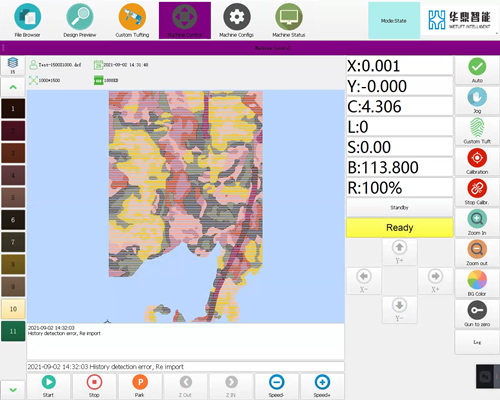

Robotuft HMI Introduction

Our self-developed Wetuft Robot Tuft Control software( HMI) a very innovative and user-friendly graphical user interface

1. it is running under Windows 10 system, support DXF and DWG format files;

2. the tufting stitches are displayed synchronously during the operation;

3. The machine is using absolute position encoder so the position information will not be lost even if the power is turned off;

4. Remote assistance: Wetuft will keep updating them once we get some upgrades by wireless remote assistance.

1. it is running under Windows 10 system, support DXF and DWG format files;

2. the tufting stitches are displayed synchronously during the operation;

3. The machine is using absolute position encoder so the position information will not be lost even if the power is turned off;

4. Remote assistance: Wetuft will keep updating them once we get some upgrades by wireless remote assistance.

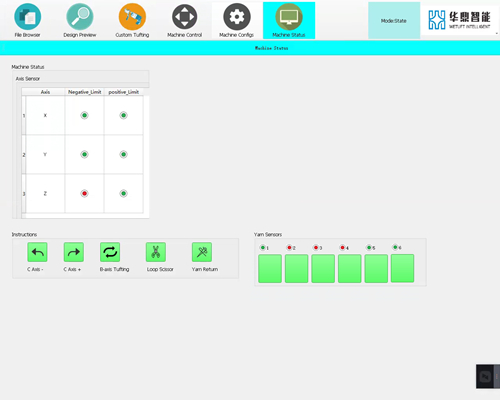

Machine Functions

1. It has 6 yarn sensors and the robot will stop immediately once the yarn breaks;

2. Operators can turn on or off according to the yarn cones freely;

3. Some functions which operators using frequently show in the machine setting;

4. Buttons functions same as remote controller and switch freely;

5. Tufting head trobleshootings more easy according to the buttons.

2. Operators can turn on or off according to the yarn cones freely;

3. Some functions which operators using frequently show in the machine setting;

4. Buttons functions same as remote controller and switch freely;

5. Tufting head trobleshootings more easy according to the buttons.

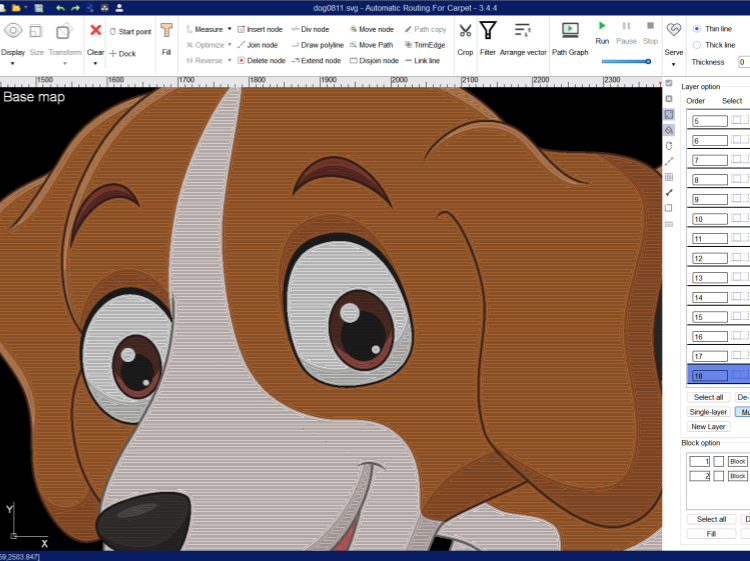

Design Preview

1. Self-developed design software named Automatic Routing For Carpet.

2. It support vector file: SVG files.

3. It can trim SVG layers, and can resize,layers color move and changes.

4. It can generate single,zigzag,spiral,offset polygon,certerline for the robot.

5. It has vector arrange function to treat the tufting orders.

2. It support vector file: SVG files.

3. It can trim SVG layers, and can resize,layers color move and changes.

4. It can generate single,zigzag,spiral,offset polygon,certerline for the robot.

5. It has vector arrange function to treat the tufting orders.

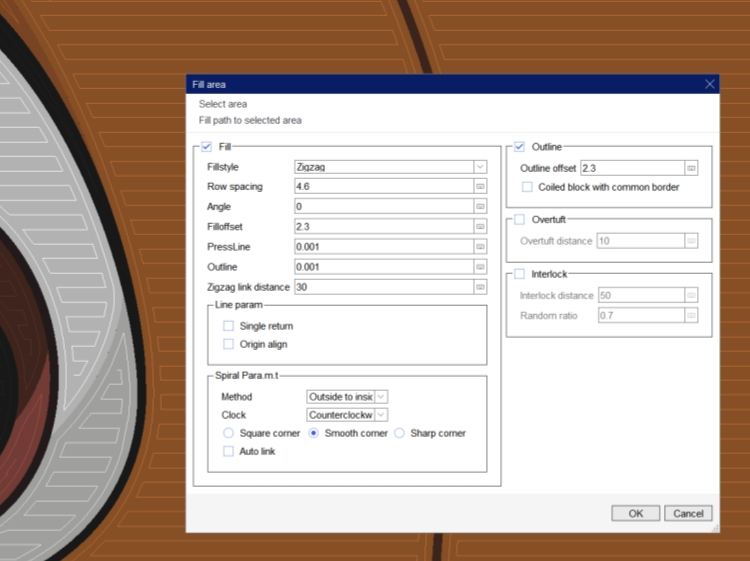

Custom Tufts

1. It has interlock, autolink, graident functions.

2. It has single return tufting order.

3. Tufting nodes can be moved, added,joined&dis-joined,extended.

4. It can draw a new line for if there is any blanks in the color blocks.

5. It can crop the big design to small parts automatic.