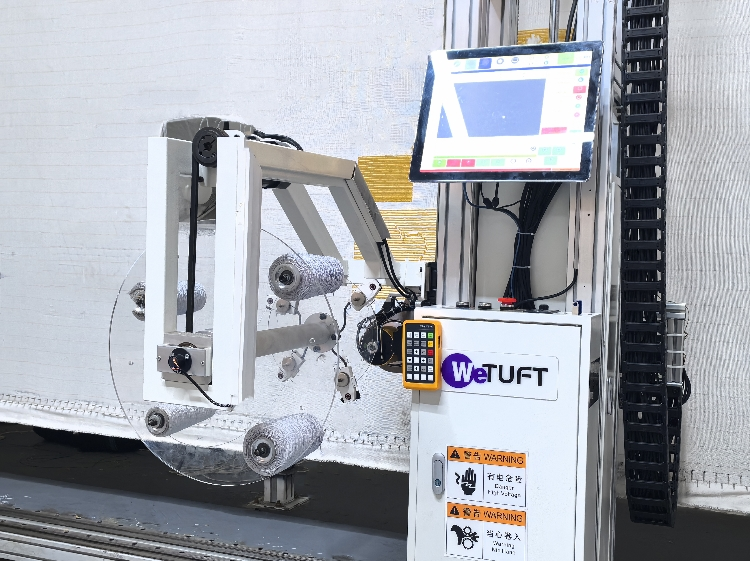

Traditional Tufting Head

1. Wireless Remote Control, improving the machine operator’s efficiency, HMI can be operated from different spots which also can be controlled by 'Machine control' page;

2. Yarn mixing function for gradient color;

3. Yarn mixing speed can be adjusted;

4. Different color control buttons for easy operating;

5. Traditional Tufting Head:

Easy for operators and hand tufting workers;

Easy for tufting gun repairing and adjusting;

Fortified tufting head, More durable

Self-developed Tufting Head Module

Mechanical tufting gun can tuft on a variety of backing fabrics and produce very detailed or over-tufted designs with high densities in short pile height which the pneumatic gun can not tufts.

Self-developed tufting head module which has the patent.

Self-developed tufting head module which has the patent.

Tufting Head Running

Mechanical tufting gun wearing parts are much cheaper than other guns;

Only need to adjust or grind the scissors and needles once they are weared;

All these parts can be purchased in your local market.

Only need to adjust or grind the scissors and needles once they are weared;

All these parts can be purchased in your local market.

ROBOTUFT PERFORMANCE

Hand tufting Workers can stands on the tufting head to repair the carpet;

Keeping the running parts clear and reduce the dust of yarn;

Easy for troubleshooting with cover;

Keeping the running parts clear and reduce the dust of yarn;

Easy for troubleshooting with cover;